Matrix Controls

MKMMS 4.0

Prompted Inspection Cycles ensure visual inspection of fabric on a periodic basis for flaws not detected by optical fabric scanners. Yarn Consumption is also continuously measured to maximize fabric yield and eliminating costly yarn overfeeding.

Key Feature of MKMMS 4.0

Web Browser Management

Quality Measurement

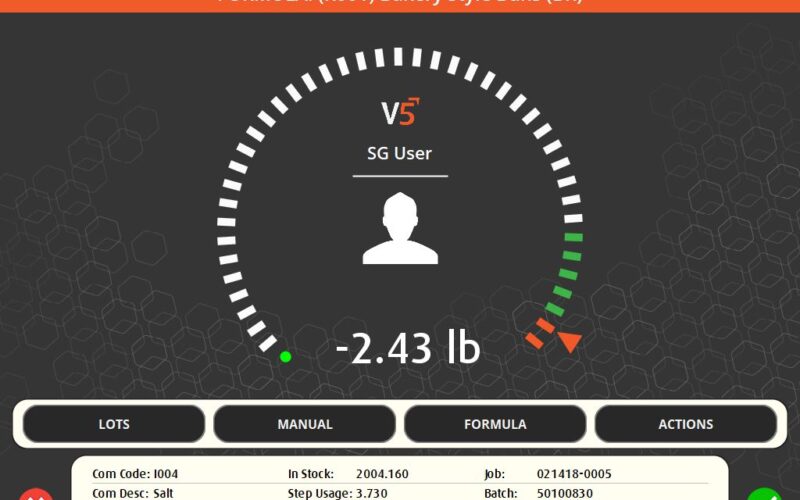

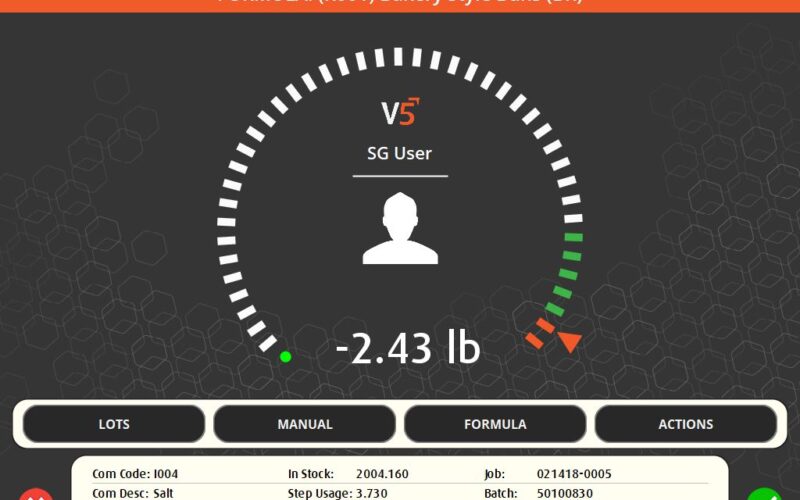

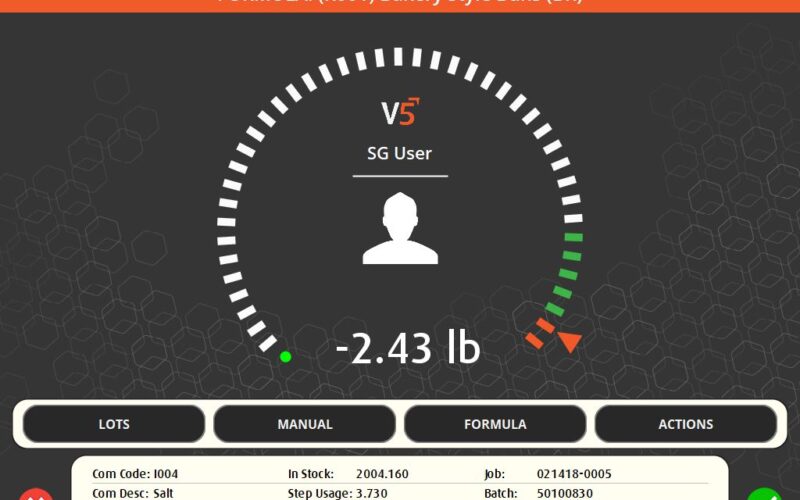

Operator Interface

Matrix Controls

Matrix Knit Monitoring Machine Software

Since its inception, textile monitoring software solutions have been utilized in the textile industry to measure the efficiency of process machinery. As time progressed, the systems have developed to monitor raw materials including fibers, yarns, chemicals and dyes. Nowadays, textile monitoring software solutions data can be used to evaluate the performance of specific machines and operators which helps management understand the quality of the process, raw material, and ultimately the finished product.

It’s all about data. Centrally collecting and crunching real-time machine data to provide management the information they need to run the operation more efficiently.

Matrix Controls

Textile Quality Software

Matrix has been a family business for over 60 years. During this period, Textile MES has been custom-designed, in-house to suit almost every process involved in controlling textile machinery. Most Matrix Control Corp customers are within the Textile industry; however, the company has diversified to include allied industries such as chemical and dye producing companies which also benefit from MES / textile monitoring software. The MES System branded as Matrix Knit Monitoring originated in 1985 and the company has built on its knowledge and reputation since then.

There are numerous benefits to a textile company implementing robust textile quality software / textile monitoring software. The automated systems can automatically stop knitting machinery from producing off quality fabric. Reduce overuse of raw materials and limit destructive machine operating conditions such as high temperatures.

Matrix Controls

Benefits of a Textile Productivity System

Eliminating overproduction of a work order is the main textile productivity system benefit. This ultimately minimizes unnecessary material usage which has a direct bottom-line impact. Textile productivity system implementations also limit destructive machine operating conditions. Conditions can include machines running too fast or at a high temperature.

Both scenarios impact the reliability and life expectancy of the machines. If a manager is responsible for hundreds of knitting machines, this can be a significant area for concern and highlighted immediately in the textile monitoring software.