This article gives an insight into the evolution of knitting techniques and how improvements have been made in such a traditional form of fashion. From an art created several thousand years ago, knitting has transformed. What was earlier an all-manual and labor-driven process has grown to be a very technical industry with better knitting technique and intelligent monitoring systems.

The Origins of Knitting: Manual Methods

A Historical Perspective

Knitting can be traced back to the ancients of Egypt in primitive form, using hand loops and the help of needles. Early practitioners relied completely on doing the work by hand, and the character and individuality of that product became unique and hard-earned labor. Common wools, silks, and other natural fibers also comprised early knitting work foundations used for today’s modern industrial development.

Tools of the Trade

The first knitting tools were extremely simple: needles made of wood, bone, or metal and hand-spun yarn. Even with such simple instruments, craftsmen could make very complicated patterns and designs. Still, the process was slow and did not allow for large-scale production.

The Industrial Revolution and the Mechanisation of Knitting

Birth of the Knitting Machine: Evolution of Knitting Technique

Evolution of knitting techniques marked a turning point in the history. The first mechanical approach came about in 1589 with the invention of the knitting frame by William Lee. The machine allowed the production of stockings and other knitted goods at much higher speeds than by hand, though its adoption was resisted by hand knitters fearing displacement.

Rise of Automated Production

During the 19th century, knitting machines finally reached a level where consistent fabrics of high quality could be produced. The factories started embracing automation, henceforth starting the mass production of textiles. Innovations such as the Jacquard attachment allowed for intricate designs to be woven into the fabric, thus changing fashion and industry.

Digital Revolution: Automatic Knitting Machines

Transition to Computer-Aided Design (CAD)

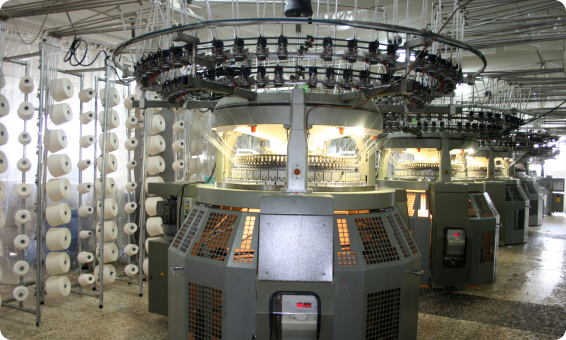

The invention of computerized knitting machines brought precision and efficiency previously unknown in this industry. These machines integrated special software in Computer-Aided Design that allowed designers to create elaborative patterns on the computer system. Once the pattern is uploaded onto the machine, flawless execution of a design with minimal errors or waste is achieved.

Benefits of Computerization

Increased Productivity: Faster production cycles and scalability.

Custom Designs: Ability to create personalized and intricate patterns.

Reduced Waste: Optimized yarn usage, which supports more sustainable practices.

Modern-Day Innovations: Smart Monitoring Systems

What are smart monitoring systems?

The latest evolution in knitting technique is smart monitoring systems, using the power of IoT and artificial intelligence. These systems are designed to oversee every aspect of the knitting process, ensuring precision and efficiency.

Key Features

Data Analysis in Real Time: Smart systems monitor such metrics as tension, speed, and fabric quality, therefore providing real-time insights into them.

Predictive Maintenance: Sensors can detect wear and tear in machinery, preventing any type of complete shutdown.

Sustainability: Smart systems ensure less waste of resources through reduced errors, hence supporting sustainable fashion.

Applications in the Industry

Mass production houses: More efficiency in garment production, textile-based technological textiles.

High-Performance Textiles: Development of special fabrics for medical, sport, and space industries.

Fashion Innovation: Giving creativity to designers to push the frontier, enabled by seamless knitting for functional clothes.

Sustainability of Knitting Technology

The modern textile industry focuses on sustainability because of consumers and environmental concern. Therefore, the knitting technique started incorporating eco-friendly practices in:

Recycled materials: Employing yarns that are made from recycled fibers.

Energy Efficiency: The machine designed for low power consumption.

Waste Reduction: Smart systems reduce the level of material wastage that happens during production.

Future in Knitting Technology

Emerging Trends

3D Knitting: Fully shaped in three dimensions, without seams, allowing comfort and perfect fit.

Wearable technology: Embedding sensors, electrical conductive fabrics for health monitoring, smart clothing, etc.

Advanced Materials:

To develop yarns that can have properties for moisture wicking, UV protection, and antimicrobial features.

Challenges Ahead

Some challenges faced by the industry, includes:

- High investment costs at the initial stages for advanced technology.

- Training employees to handle the new systems.

- Balancing automation with preservation of traditional craftsmanship.

Conclusion

From very humble beginnings in the use of manual methods to the integration of smart monitoring systems, knitting technique has undergone continuous evolution to meet the constantly changing demands of the world. Today, blending tradition and innovation, would mean knitting will continue to remain both an art and a science for fashion and textiles that head into the future.